Multi point cutting tool pdf

Abstract: Numerical simulation of milling process needs an accurate model of cutting tool. In this paper, we describe the In this paper, we describe the methodology developed to design flat and ball end mills in three-dimensional configuration.

The tool having only one cutting point or edge is called single point cutting tool such as tool used for turning, boring shaping or planning, while the tool having more than one cutting point or edge is called multi point cutting tool such as tool used for drilling, milling broaching. Single point cutting tools

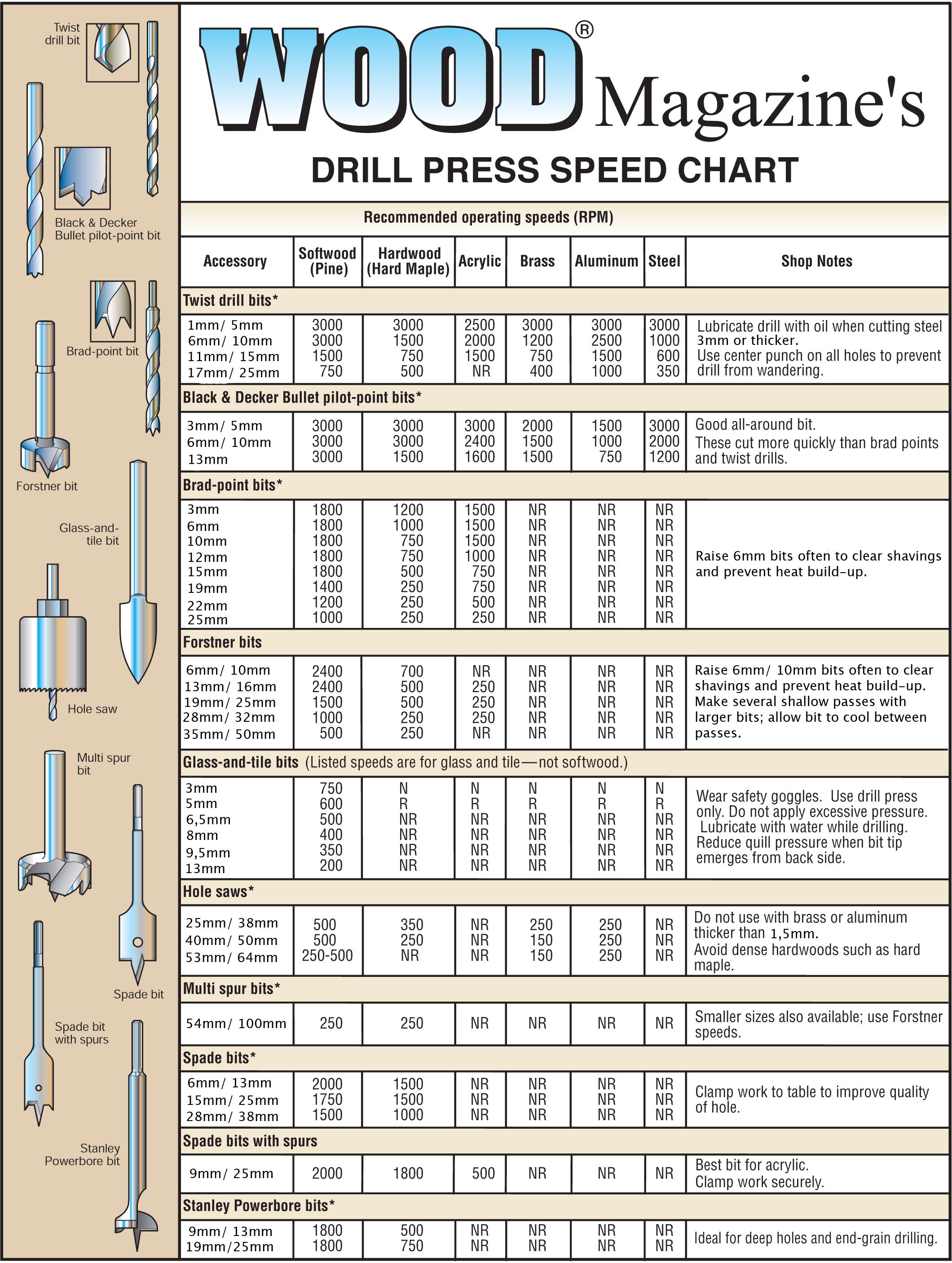

use of multi-point cutting tools called drill or drill bits. Various cutting tools are 297blind hole in a solid material. It has found that high production machining and drilling

theory of metal cutting The metal cutting is done by a relative motion between the work piece and the hard edge of a cutting tool. Metal cutting could be done either by a single point cutting tool or a multi point cutting tool.

Design of Multi point cutting tools 2 DESIGN OF CUTTING ELEMENT: To design the cutting element of the tool, it is necessary to know the kinetics of cutting. The motions in various metal cutting machines tools are made up of linear and rotary motions.

The single point cutting tool held properly in the tool post is mounted on a reciprocating ram. The reciprocating motion of the ram is obtained by a quick return

1.3.2 Multi Point Cutting Tool 1.4 Types of Machine Tools 1.5 Operational Issues in Tool Engineering 1.6 Summary 1.7 Key Words 1.1 INTRODUCTION Tool engineering is a vital area of production engineering. It includes metal cutting, pressing, and various work holding devices. Metal cutting is the operation in which thin layer of metal is removed by wedge shaped tool. Metal cutting is commonly

using Multi Point Cutting Tool for Surface Finish Prof. (Dr) .V. R. Naik1, Mr.G.C.Mekalke2, Mr.A.V.Sutar2 assess the performance of cutting tools under various conditions. This study aims to determine the cutting conditions that will result in the lowest value of surface roughness. Surface roughness is one of the most important requirements in machining process, as it is considered an

Request PDF on ResearchGate Surface modeling of multi-point, multi-flute cutting tools Cutting tools are usually represented by two-dimensional representation schema(s). The two-dimensional

Cutting tools may be classified according to the number of major cutting edges (points) involved as follows: • Single point: e.g., turning tools, shaping, planning and slotting tools and

4/10/2016 · Multi point cutting tool In this two or more single point cutting tools arranged together as a unit. The rate of machining is more & surface finish is also better in this case.

Abstract. A multipoint tool can be regarded as a series of two or more cutting parts secured to a common body. The majority of multipoint tool are intended to be rotated and the workpiece is moved in a plane normal (as in milling) or parallel (as in drilling) to the axis of spindle rotation.

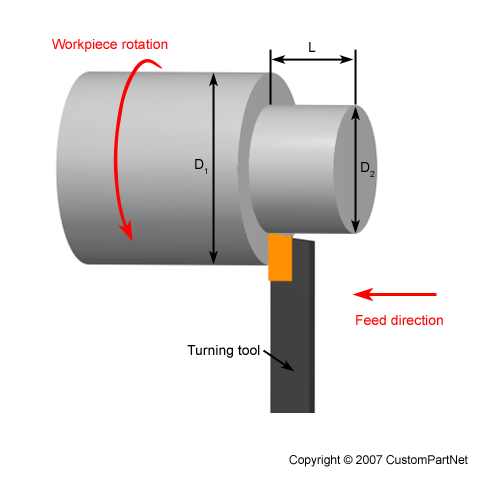

tool. For a multi-point tool, the cutting feed is also equal to the feed per tooth, measured in inches per tooth (IPT), multiplied by the number of teeth on the cutting tool. Cutting speed – The speed of the workpiece surface relative to the edge of the cutting tool during a cut, measured in surface feet per minute (SFM). Spindle speed – The rotational speed of the spindle and the work

Comparison between multi-point and other 5-axis tool

Turning Process Defects Equipment CustomPart.Net

a) Broaching is the cutting of a machinable material using single point cutting tool by moving the tool linearly relative to the work in the direction of tool axis b) Broaching is the cutting of a machinable material using multiple tooth cutting tools

International Journal of Machine Tools & Manufacture 40 (2000) 185–208 Comparison between multi-point and other 5-axis tool positioning strategies

cutting operation due to the multi-point cutting tool employed. End milling looks a lot like face milling but uses a smaller cutter. It is a type of peripheral milling used for profiling and slotting operations. Much like peripheral milling, in end milling the undeformed chip thickness is variable throughout the cutting operation, but the undeformed chip width corresponds to the depth of cut

multi-point cutting tool. Broaching Machine: a machine that uses a specially shaped broaching tool having a series of progressively larger teeth to cut internal or external shapes on a workpiece.

This paper examines the potential of a new tool positioning strategy where the desired surface is machined at more than one point of contact between the desired surface and the cutting tool. The

Single-point cutting tool As distinguished from other cutting tools such as a The cutting edge is ground to suit a particular machining operation and may be re sharpened or reshaped as needed. The ground tool bit is held rigidly by a tool holder while it is cutting.

cutting action, respectively (helical teeth lower tooth load, tool forces, chatter) • In conventional (up milling) the maximum chip thickness is at the end of the • Machining

Multi-Point Astragal Cut Down Instructions 4 a. Locate the T-bar on the narrow side of the astragal and slide it out of the lower end of the astragal body, far enough to

4 State the types of form tools and also state the advantages of multi-point cutting tools. 5 Differentiate between „Orthogonal Cutting‟ and „Oblique Cutting‟ methods. 6 State the methods of measurement of cutting power and explain any one method in brief.

Fundamental Of Metal Cutting And Machine Tools Pdf Recent advances in super-hard cutting tool materials, tool geometries, and Fundamentals of Machining & Machine Tools 2Ed – Geoffrey Boothroyd (PDF) (Size: 38.67 Fundamentals of

These cutting tools can be classified as single point cutting tool, used in lathe, planer and, slotter and multi point cutting tool used in milling, drilling and broaching . Figure 2.1: Nomenclature of a single point cutting tool

Machine tool – Tool materials: In order to remove chips from a workpiece, a cutting tool must be harder than the workpiece and must maintain a cutting edge at the temperature produced by the friction of the cutting action. Steel with a carbon content ranging from 1 to 1.2 percent was the earliest material used in machine tools. Tools made of

of cutting, low wastage of material, good quality of dimensional accuracy and low power consumption. Saw is a multipoint cutting tool, which is used in sawing operation.

Luis Hoyos. Download with Google Download with Facebook or download with email. Fundamentals of tool design – Society of manufacturing engineers.pdf

Machine tool Britannica.com

b) a single-point cutting tool used on lathes for creating circular parts c) a round, end cutting tool with one or more cutting lips and one or more straight or helical flutes used to …

Design of single point cutting tool is an important aspect of tool engineering. This unit This unit deals with the design of tool shank, design of single point cutting tool, and various forces

use of multi-point cutting tools called drills or drill bits. Drilling is a continuous machining process. Various cutting tools are available for drilling, but the most common is the twist drill. Wide variety of drill processes are available to serve different purposes (core drilling, step drilling, counter boring, counter sinking, reaming, center drilling, gun drilling etc.).With the rapidly

single point cutting tool nomenclature animation I concept of rake and clearance angles then ii systems of description of tool geometry b Study and show tools.It is the edge on the face of the tool which removes the material from the work piece.

As its name indicates, a tool that has a single point for cutting purpose is called single point cutting tool. It is generally used in the lathe machine , shaper machine etc. It is used to remove the materials from the workpiece. – reproductive toxicity studies ich guidelines It is commonly used for single point lathe cutting tools and multi point cutting tools such asdrills, reamers and milling cutters.Cemented CarbidesAn extremely hard material made from tungsten powder. Carbide tools are usually used in the form ofbrazed or clamped tips. High cutting speeds may be used and materials difficult to cut with HSS may bereadily machined using carbide tipped tool.8

– For Multi-point inserts it is essential that the recommendations on page C80 are used. – For V-profile inserts the recommended number of passes that is used

nomenclature of multipoint cutting tool,Ask Latest information,Abstract,Report,Presentation (pdf,doc,ppt),nomenclature of multipoint cutting tool technology discussion,nomenclature of multipoint cutting tool paper presentation details

• Multi Point tools • Milling cutters, Taps, Reamers. 03‐09‐2018 3 Single Point Cutting Tool Tool Inserts Insert Shapes Twist Drills and End Mills

CHAPTER – II PROFILE OF CUTTING TOOL INDUSTRY 2.1 HISTORICAL GROWTH The story of metal cutting tool is the story of civilization. When the primitive man laid aside his stone weapons for tools of copper and bronze, the shift

cutting speeds, using a tool life criterion of 0.50 mm flank wear ©2002 John Wiley & Sons, Inc. M. P. Groover, “Fundamentals of Modern Manufacturing 2/e” Figure 23.5 -Natural log-log plot of cutting speed vs tool …

Design of Multi point cutting tools 1 Chapter 4 Multipoint cutting tools FIGURE 11.1 – TYPES OF CUTTING TOOLS Depending upon the construction of the cutting tool, it is classified as: 1) Solid tools 2) Tipped cutting tools.

Machine tool, any stationary power-driven machine that is used to shape or form parts made of metal or other materials. The shaping is accomplished in four general ways: (1) by cutting excess material in the form of chips from the part; (2) by shearing the material; (3) by squeezing metallic parts

The cutter is typically a single-point cutting tool that is also secured in the machine, although some operations make use of multi-point tools. The cutting tool feeds into the rotating workpiece and cuts away material in the form of small chips to create the desired shape.

Point Tools and Tool Posts (ASA B5.22-1950), Section 1 of which covered terminology and definitions for single-point cutting tools. Late in 1955, Technical …

Abstract: Broach tool is a multi-point cutting tool consisting a bar having surface containing a series of cutting teeth or edges which are gradually increase …

Machine tool Tool materials Britannica.com

Fundamental Of Metal Cutting And Machine Tools Pdf

INVESTIGATION OF SURFACE FINISH AND MRR DURING

CHAPTER II PROFILE OF CUTTING TOOL INDUSTRY

design and selection of single and multipoint cutting tool

REVIEW OF INFLUENCE OF DIFFERENT CUTTING ANGLES OF

Implementation of Response Surface Methodology for

Fundamentals of tool design Society of manufacturing

– Surface modeling of multi-point multi-flute cutting tools

UNIT 7 METAL SAWING Metal Sawing IGNOU

FUNDAMENTALS OF METAL CUTTING KSU Faculty

INFLUENCE OF CUTTING PARAMETERS ON CUTTING FORCE AND

23 thoughts on “Multi point cutting tool pdf”

Comments are closed.

Machine tool – Tool materials: In order to remove chips from a workpiece, a cutting tool must be harder than the workpiece and must maintain a cutting edge at the temperature produced by the friction of the cutting action. Steel with a carbon content ranging from 1 to 1.2 percent was the earliest material used in machine tools. Tools made of

Fundamental Of Metal Cutting And Machine Tools Pdf

Machine tool Tool materials Britannica.com

Machine tool Britannica.com

Multi-Point Astragal Cut Down Instructions 4 a. Locate the T-bar on the narrow side of the astragal and slide it out of the lower end of the astragal body, far enough to

Comparison between multi-point and other 5-axis tool

libvolume6.xyz

use of multi-point cutting tools called drill or drill bits. Various cutting tools are 297blind hole in a solid material. It has found that high production machining and drilling

SINGLE-POINT CUTTING TOOL BrainKart

UNIT 7 METAL SAWING Metal Sawing IGNOU

CUTTING TOOL TECHNOLOGY 國立中興大學

This paper examines the potential of a new tool positioning strategy where the desired surface is machined at more than one point of contact between the desired surface and the cutting tool. The

Surface modeling of multi-point multi-flute cutting tools

libvolume6.xyz

Single point cutting tool nomenclature pdf WordPress.com

Fundamental Of Metal Cutting And Machine Tools Pdf Recent advances in super-hard cutting tool materials, tool geometries, and Fundamentals of Machining & Machine Tools 2Ed – Geoffrey Boothroyd (PDF) (Size: 38.67 Fundamentals of

Design and manufacturing of square broach tool Balaji D

FUNDAMENTALS OF METAL CUTTING KSU Faculty

cutting operation due to the multi-point cutting tool employed. End milling looks a lot like face milling but uses a smaller cutter. It is a type of peripheral milling used for profiling and slotting operations. Much like peripheral milling, in end milling the undeformed chip thickness is variable throughout the cutting operation, but the undeformed chip width corresponds to the depth of cut

Fundamentals of tool design Society of manufacturing

Multiple Point Cutting Processes SpringerLink

Request PDF on ResearchGate Surface modeling of multi-point, multi-flute cutting tools Cutting tools are usually represented by two-dimensional representation schema(s). The two-dimensional

Optimization Of Drilling Parameters For Minimum Surface

b) a single-point cutting tool used on lathes for creating circular parts c) a round, end cutting tool with one or more cutting lips and one or more straight or helical flutes used to …

INFLUENCE OF CUTTING PARAMETERS ON CUTTING FORCE AND

multipoint-cutting-tool Design of Multi point cutting

CHAPTER – II PROFILE OF CUTTING TOOL INDUSTRY 2.1 HISTORICAL GROWTH The story of metal cutting tool is the story of civilization. When the primitive man laid aside his stone weapons for tools of copper and bronze, the shift

libvolume6.xyz

multi-point cutting tool. Broaching Machine: a machine that uses a specially shaped broaching tool having a series of progressively larger teeth to cut internal or external shapes on a workpiece.

SINGLE-POINT CUTTING TOOL BrainKart

design and selection of single and multipoint cutting tool

4/10/2016 · Multi point cutting tool In this two or more single point cutting tools arranged together as a unit. The rate of machining is more & surface finish is also better in this case.

SINGLE-POINT CUTTING TOOL BrainKart

CHAPTER II PROFILE OF CUTTING TOOL INDUSTRY

4 State the types of form tools and also state the advantages of multi-point cutting tools. 5 Differentiate between „Orthogonal Cutting‟ and „Oblique Cutting‟ methods. 6 State the methods of measurement of cutting power and explain any one method in brief.

Design and manufacturing of square broach tool Balaji D

cutting speeds, using a tool life criterion of 0.50 mm flank wear ©2002 John Wiley & Sons, Inc. M. P. Groover, “Fundamentals of Modern Manufacturing 2/e” Figure 23.5 -Natural log-log plot of cutting speed vs tool …

Optimization Of Drilling Parameters For Minimum Surface

Fundamental Of Metal Cutting And Machine Tools Pdf Recent advances in super-hard cutting tool materials, tool geometries, and Fundamentals of Machining & Machine Tools 2Ed – Geoffrey Boothroyd (PDF) (Size: 38.67 Fundamentals of

INVESTIGATION OF SURFACE FINISH AND MRR DURING

Optimization Of Drilling Parameters For Minimum Surface

theory of metal cutting The metal cutting is done by a relative motion between the work piece and the hard edge of a cutting tool. Metal cutting could be done either by a single point cutting tool or a multi point cutting tool.

INFLUENCE OF CUTTING PARAMETERS ON CUTTING FORCE AND

It is commonly used for single point lathe cutting tools and multi point cutting tools such asdrills, reamers and milling cutters.Cemented CarbidesAn extremely hard material made from tungsten powder. Carbide tools are usually used in the form ofbrazed or clamped tips. High cutting speeds may be used and materials difficult to cut with HSS may bereadily machined using carbide tipped tool.8

Surface modeling of multi-point multi-flute cutting tools

The tool having only one cutting point or edge is called single point cutting tool such as tool used for turning, boring shaping or planning, while the tool having more than one cutting point or edge is called multi point cutting tool such as tool used for drilling, milling broaching. Single point cutting tools

Surface modeling of multi-point multi-flute cutting tools

Turning Process Defects Equipment CustomPart.Net

Fundamental Of Metal Cutting And Machine Tools Pdf

Point Tools and Tool Posts (ASA B5.22-1950), Section 1 of which covered terminology and definitions for single-point cutting tools. Late in 1955, Technical …

Surface modeling of multi-point multi-flute cutting tools

This paper examines the potential of a new tool positioning strategy where the desired surface is machined at more than one point of contact between the desired surface and the cutting tool. The

Single point cutting tool nomenclature pdf WordPress.com

Fundamental Of Metal Cutting And Machine Tools Pdf

use of multi-point cutting tools called drills or drill bits. Drilling is a continuous machining process. Various cutting tools are available for drilling, but the most common is the twist drill. Wide variety of drill processes are available to serve different purposes (core drilling, step drilling, counter boring, counter sinking, reaming, center drilling, gun drilling etc.).With the rapidly

nomenclature of multipoint cutting tool easystudy.info

libvolume6.xyz

2012 manufacturing tools & machining solutions

Design of Multi point cutting tools 1 Chapter 4 Multipoint cutting tools FIGURE 11.1 – TYPES OF CUTTING TOOLS Depending upon the construction of the cutting tool, it is classified as: 1) Solid tools 2) Tipped cutting tools.

Single point cutting tool nomenclature pdf WordPress.com

CUTTING TOOL TECHNOLOGY 國立中興大學

use of multi-point cutting tools called drills or drill bits. Drilling is a continuous machining process. Various cutting tools are available for drilling, but the most common is the twist drill. Wide variety of drill processes are available to serve different purposes (core drilling, step drilling, counter boring, counter sinking, reaming, center drilling, gun drilling etc.).With the rapidly

Multi-Point Astragal – Cut Down Instructions

libvolume6.xyz

Comparison between multi-point and other 5-axis tool

The tool having only one cutting point or edge is called single point cutting tool such as tool used for turning, boring shaping or planning, while the tool having more than one cutting point or edge is called multi point cutting tool such as tool used for drilling, milling broaching. Single point cutting tools

FUNDAMENTALS OF METAL CUTTING KSU Faculty

UNIT 7 METAL SAWING Metal Sawing IGNOU